Industrial engineering: processes, treatment and recycling of air, water and waste

_Support for manufacturers on all operational issues to reduce emissions

Drawing on its expertise in environmental diagnostics, Ginger supports its industrial clients in all of their operational challenges to reduce air, water, and waste emissions, recycle water and waste, recover materials and waste energy, optimize processes, and reduce energy consumption and greenhouse gas emissions through the use of new energies (geothermal, hydrogen, etc.).

From measuring emissions to designing and implementing solutions, Ginger works with you across the entire manufacturing value chain to develop and implement the energy and environmental transition.

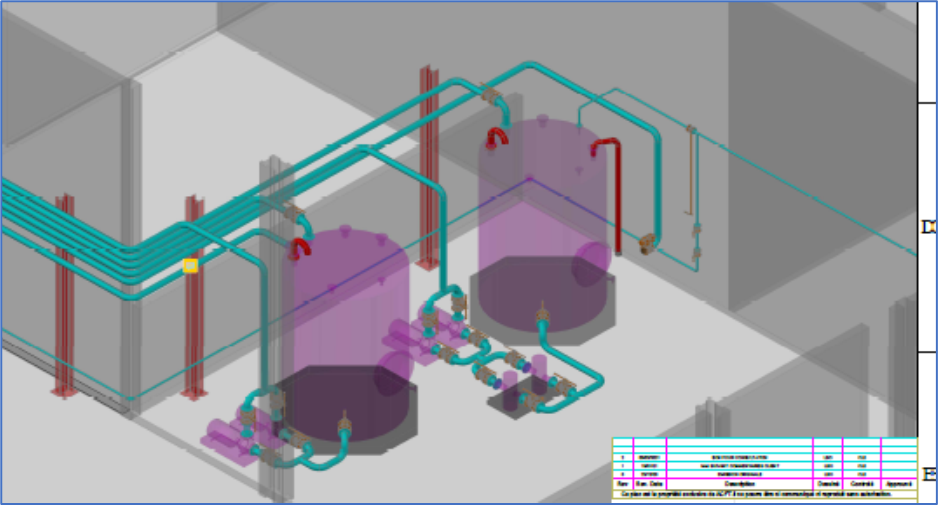

Water and industrial effluent treatment

Treatment of atmospheric emissions

Waste treatment, recycling and recovery

Water supply, recycling and saving

Mining and mineral processing

Metal industry

Fertiliser industry

Agribusiness

Energy and carbon

_A word from the expert

"In the current context of pressing environmental challenges, industry is faced with increasingly strict and restrictive regulations. The need for industrial players to comply with current regulations while responding to climate and environmental issues is not only imperative, but is also essential to guarantee the sustainability of our planet, our economies and the long-term future of our businesses.

Implementing these regulations is complex for manufacturers. Initiatives to save water, recycle and re-use it, or comply with standards for atmospheric emissions often involve major investment in terms of technology, work and staff training, and require specific expertise. How can industrial processes be optimised? How can atmospheric and aqueous effluent treatment systems be installed? How can the most appropriate water-saving measures be introduced, both technically and financially?

Our experience in a wide range of sectors (agri-food, petrochemicals, refining, paper, chemicals, pharmaceuticals, metal work, transport, energy, etc.) enables us to support manufacturers in identifying, sizing and implementing environmental projects that meet these regulatory requirements, as well as in seeking subsidies. Our mission is to help you meet future environmental challenges while preserving the viability of your industrial activities."

_Why the Ginger Group?

_Cutting-edge expertise

- Extensive experience on complex projects

- The technical expertise of our teams

- Complementary skills within the Group

_Industrial expertise

- A team of process engineers from the world of industry

- Support for all industrial sectors, from SMEs to major groups

- A global approach integrating technical, economic and regulatory aspects

_Independence and commitment

- Independent analysis and recommendation of appropriate solutions

- Support throughout the project cycle, with us at your side every step of the way

_Innovation

- Integrating innovations and techniques into engineering expertise in processes, measurement and control

- Geothermal energy, hydrogen, development of low-carbon recycled materials, etc. We work alongside you in design and implementation

Contact an expert in industrial process engineering

Can a balance be struck between the development of industrial activities and water resource sustainability?

In recent years, the various episodes of drought, accentuated by climate change, have put pressure on water resources and led to restrictions for all users. For industrial companies, this raises the double issue of ensuring the sustainability of resources and of reducing consumption.

Studies of the resource, water assessments at different scales, and process studies to reduce consumption can all provide a solution for industrial companies by reducing consumption and maintaining nominal activity throughout the drought shutdown period as a result of these water savings.